How PW and WFI Storage and Distribution Systems Support the Pharmaceutical Industry

In the pharmaceutical industry, the quality of water used directly impacts the safety, efficacy, and compliance of drug products. Among the various water types employed, Purified Water (PW) and Water for Injection (WFI) are critical for processes ranging from formulation to equipment cleaning. However, achieving the required water quality is not enough; maintaining it through effective storage and distribution systems is equally vital.

Purpose and Importance of PW and WFI

Purified Water (PW) is primarily used for non-parenteral applications such as cleaning, rinsing, and as an ingredient in oral and topical formulations. It must meet stringent physicochemical standards and be free from microbial contaminants.

Water for Injection (WFI), on the other hand, is used in the production of parenteral products and for final rinsing of equipment and containers in aseptic processing. WFI must meet even stricter specifications, including low endotoxin levels and near-sterility, as per global pharmacopeial standards such as USP, EP, and JP.

Once generated, PW and WFI must be stored and delivered to points of use without compromising their quality. This is where high-integrity storage and distribution systems come into play.

Design Considerations for Storage and Distribution Systems

PW and WFI distribution systems must be designed with meticulous attention to hygiene, material compatibility, thermal control, and compliance. The primary goals are to:

- Maintain chemical and microbial integrity

- Prevent recontamination

- Support sanitization and validation

- Enable continuous monitoring and control

- Materials and Construction

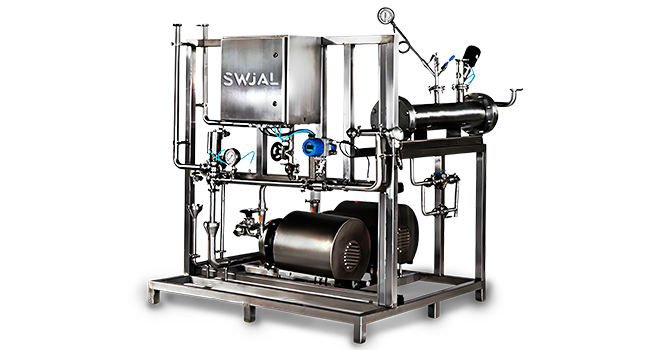

All wetted parts of the system, including tanks, piping, and valves, are constructed using electropolished SS316L stainless steel with <0.6 μm surface finish. Orbital welding is used for all joints to eliminate crevices and dead legs that can harbor microbial growth.

Distribution Loop Design

The distribution loop is kept in continuous circulation at velocities above 1.5 m/s to prevent stagnation. The system is designed with a sloped return line for complete drainage and includes zero dead leg valves, sanitary sample ports, and diaphragm pumps for controlled flow.

Thermal Control

WFI Plant is often stored and circulated at elevated temperatures (typically 80–85°C) to ensure microbial control, while PW may be maintained at ambient or slightly elevated temperatures. The use of double-jacketed piping and insulated storage tanks helps maintain these conditions

Automation and Real-Time Monitoring

Modern systems are integrated with PLC or SCADA automation platforms that allow pharmaceutical operators to:

- Monitor critical parameters such as conductivity, TOC, temperature, pressure, and microbial load

- Log data for 21 CFR Part 11 compliance

- Trigger alarms and corrective actions in case of deviations

- Schedule and control sanitization processes

These features ensure that the water quality remains within validated limits and facilitate compliance with GMP, FDA, and EMA regulations.

Sanitization Methods

To control microbial contamination, both PW and WFI systems are equipped with periodic or continuous sanitization capabilities, such as:

- Hot water sanitization (up to 85°C)

- Pure steam sterilization

- Chemical sanitization using ozone or hydrogen peroxide

- UV disinfection as an additional safeguard

- Sanitization cycles are automated and validated, ensuring thorough coverage and repeatability.

- Validation and Documentation

Validation is a regulatory requirement and a best practice. The system must be qualified through IQ/OQ/PQ protocols, and regular monitoring must be conducted to ensure ongoing performance. Critical control points are identified for routine sampling and microbial testing.

Comprehensive documentation—including audit trails, batch records, and sanitization logs—supports regulatory audits and ensures traceability across the water system’s lifecycle.

Applications in Pharmaceutical Manufacturing

PW and WFI are essential for:

- Formulation of drug products (oral, topical, injectable)

- Cleaning and rinsing of production vessels, pipelines, and container-closure systems

- Preparation of culture media and other biopharmaceutical processes

- Sterile manufacturing and aseptic filling lines

The quality of water delivered to these points of use has a direct effect on product stability, patient safety, and regulatory compliance.

Benefits of Advanced PW and WFI Systems

- An optimized storage and distribution system offers numerous advantages:

- Consistent product quality through reliable water supply

- Reduced contamination risks, minimizing batch rejection and product recalls

- Improved operational efficiency via automation and predictive maintenance

- Scalability to support facility expansions or increased production volumes

- Audit readiness through traceable records and compliance with international guidelines

Moreover, modern systems are increasingly incorporating energy-efficient features such as variable-speed pumps, thermal recovery systems, and reduced water loss during sanitization—supporting the pharmaceutical industry's drive toward sustainability.

Conclusion

In the pharmaceutical industry, water is more than just a utility—it is a critical raw material. The proper storage and distribution of Purified Water and Water for Injection ensures that the stringent requirements for drug safety, quality, and regulatory compliance are met. Investing in a well-engineered and validated system not only mitigates risk but also enhances operational efficiency and audit readiness.

As the pharmaceutical landscape evolves and regulatory expectations intensify, robust PW and WFI systems remain an indispensable backbone of compliant and high-performance pharmaceutical manufacturing.

No comments:

Post a Comment