In industries where precision and safety are paramount—such as pharmaceuticals, biotechnology, semiconductors, and food processing—the quality of water cannot be compromised. While purification technologies like RO, EDI, or distillation create high-purity water, its integrity must be preserved until it is delivered at the point of use. The design of storage and distribution systems plays a pivotal role in this process, ensuring that purified water remains compliant with international standards and suitable for critical operations.

Why System Design is Crucial

Water generation is only the first stage. If the subsequent storage or distribution network is poorly engineered, it can become a source of contamination. Stagnation, microbial growth, or chemical leaching can all deteriorate water quality. Hence, distribution loops must be constructed to maintain constant circulation, minimize dead legs, and sustain uniform pressure. For industries where downtime or regulatory non-compliance has severe consequences, these design choices directly impact both product quality and operational efficiency.

Essential Elements of System Design

Several key parameters must be considered to achieve reliability and purity in industrial water systems:

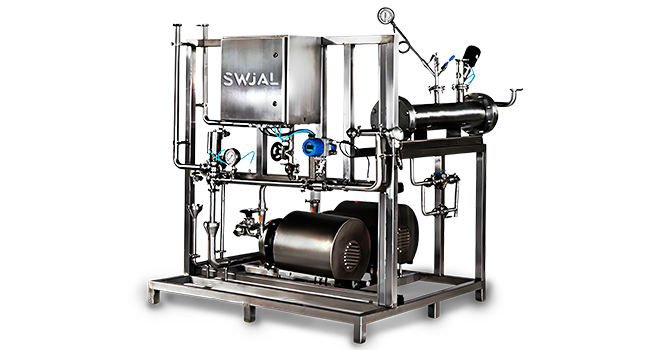

Material Choice – Stainless steel 316L remains the gold standard for tanks and piping due to its durability, resistance to corrosion, and hygienic properties. In certain applications, high-grade polymers are used for their chemical resistance and flexibility.

Surface Quality – Polished or electropolished surfaces with very low roughness (Ra ≤ 0.6 µm) prevent microbial attachment and biofilm formation, extending system lifespan.

Hygienic Construction – Features such as orbital welds, adequate slopes for drainage, and zero-dead-leg valves ensure complete sterilization and cleanability of the system.

Water Velocity – A circulation speed between 1–3 m/s is typically maintained to avoid stagnation and discourage microbial contamination inside pipelines.

Sanitization Methods – Depending on the industry, systems are designed with hot water sanitization, ozone dosing, or UV disinfection to maintain microbiological safety.

Features of Advanced Storage Tanks

Storage tanks act as an intermediary between water generation and its final distribution. Modern designs include:

Sterile Vent Filters – Equipped with hydrophobic membranes to block airborne contaminants.

CIP Arrangements – Integrated spray balls allow thorough automated cleaning.

Insulation & Cladding – Maintain thermal stability and reduce energy loss.

Instrumentation – Level transmitters, temperature sensors, and pressure indicators ensure precise monitoring and control.

These features collectively guarantee that the water stored remains as pure as when it was generated.

Reliability in Distribution Loops

The distribution system must not only deliver water in the right quantity but also preserve its integrity. This is achieved through:

Continuous Recirculation – Loop-based designs reduce water stagnation and maintain uniform quality across all outlets.

Real-Time Monitoring – Instruments track conductivity, TOC, temperature, and flow rate, ensuring adherence to pharmacopeial requirements.

Automation – PLC-driven systems provide predictive maintenance, alarm management, and data logging for validation during regulatory audits.

Applications in Critical Industries

Pharmaceuticals – Essential for drug formulation, cleaning validation, and sterile manufacturing environments.

Biotechnology – Provides contamination-free water for sensitive processes like cell culture and fermentation.

Electronics & Semiconductors – Supplies ultra-pure water with extremely low conductivity, critical for wafer and chip production.

Food & Beverage – Ensures hygienic water circulation to maintain product safety and flavor consistency.

Compliance with International Standards

Industrial water systems must conform to global regulatory frameworks. Guidelines from USFDA, EMA, WHO, and technical standards like ISPE Baseline Guides set expectations for system validation. Pharmacopeial benchmarks such as USP, EP, and JP further define purity requirements. Meeting these ensures that systems remain compliant during inspections and safeguard operational approvals.

Advantages of Optimized Design

Consistent water quality across all points of use

Minimized microbial risks and contamination

Compliance with international regulations

Improved operational reliability and uptime

Cost savings through reduced maintenance and extended system life

Final Thoughts

Purified water generation is only effective when supported by a well-engineered storage and distribution system. By combining hygienic design, smart automation, and regulatory compliance, industries can secure uninterrupted access to high-purity water while protecting product integrity.

SWJAL PROCESS Pvt. Ltd. designs and manufactures Industrial Water Storage and Distribution Systems that meet stringent global standards, ensuring reliability, purity, and long-term operational excellence.