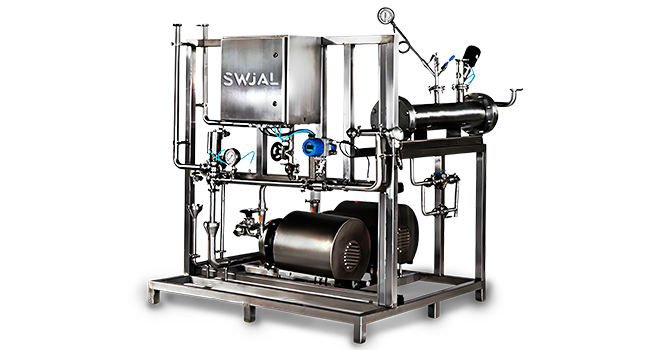

Water is a major ingredient and cleaning agent in the food and beverage industry. To meet stringent hygiene and safety requirements, a Purified Water Storage and Distribution System ensures the consistent delivery of high-quality water to all points of use.

Food-grade systems are typically constructed with SS316L stainless steel and designed for CIP compatibility. Recirculating distribution loops prevent stagnation and biofilm formation, while the use of hygienic valves and fittings minimizes contamination risk. Flow rates, temperatures, and microbial levels are constantly monitored using PLC/SCADA automation, which helps maintain regulatory compliance with FSSAI, WHO, and other standards.

Sanitization processes include hot water, steam, or ozone treatment to ensure microbial integrity. These systems are validated and documented to comply with HACCP and GMP standards. Applications include the rinsing of packaging materials, ingredient blending, bottle washing, and final rinse before product filling.

Implementing an advanced purified water system improves product consistency, reduces microbial risks, and supports long shelf-life. This makes it an essential investment for any food or beverage manufacturer committed to quality and safety.

|

| Purified Water Storage and Distribution System for the Food & Beverage Industry |

With rising consumer demand for clean label and preservative-free products, the importance of maintaining water purity in food and beverage production has never been greater. Any variation in water quality can impact taste, shelf life, and safety. High-purity distribution systems help avoid these issues by ensuring that water used in recipes and rinsing processes remains free from contaminants.

Furthermore, sustainable water systems with energy-efficient features and water recovery mechanisms are becoming increasingly popular. These systems help manufacturers reduce water consumption, cut utility costs, and demonstrate corporate responsibility. With integrated monitoring, they also provide real-time alerts for deviations, enabling swift corrective action before quality is compromised.

No comments:

Post a Comment