In biotechnology, the integrity of research and bioprocesses relies heavily on the purity of the water used. A Purified Water Storage and Distribution System tailored for the biotech sector ensures high-quality water reaches every critical point of use, thereby safeguarding sensitive applications like cell culture, fermentation, and media preparation.

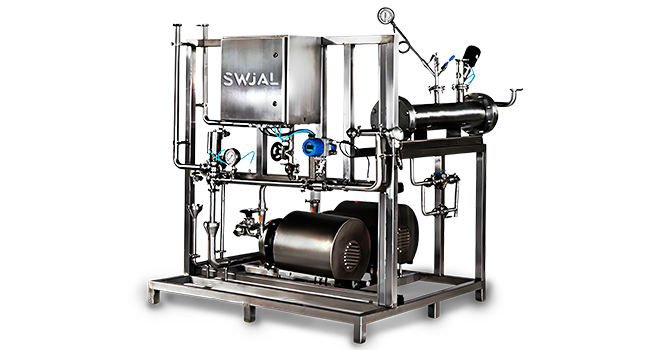

The system must meet stringent standards such as USP and EP specifications and be capable of maintaining microbial and chemical purity. Constructed using SS316L stainless steel with orbital welding, the system is designed to minimize microbial growth and contamination. Distribution loops are designed for continuous recirculation with flow velocities exceeding 1.5 m/s, and equipped with ultra-sanitary diaphragm valves, zero dead leg points, and hygienic clamps.

Automation and real-time monitoring via PLC/SCADA allow for comprehensive data logging and immediate corrective actions if parameters deviate. Sanitization is typically done using heat (at 85°C or higher) or chemical agents like ozone. Systems can also integrate UV lamps and fine filters for additional microbial control.

Key applications include the preparation of media for recombinant DNA processes, rinsing of bioreactors, and ensuring the sterility of downstream processes like protein purification. These systems help maintain reproducibility and reduce the risk of batch contamination.

As biotechnology continues to evolve, the complexity of processes increases, demanding even higher standards of water purity and system reliability. Advanced purified water systems are being designed with modular architectures that allow for easy customization and upgrades. This modularity ensures that as biotech operations grow or shift focus, the water system can adapt without requiring complete overhauls, thus saving both time and cost.

Additionally, the integration of smart technologies, such as predictive maintenance algorithms and remote diagnostics, offers enhanced control over water system operations. These features help in early detection of issues, minimizing risk to ongoing processes and ensuring uninterrupted research and production. Combined with electronic record keeping, this makes regulatory compliance more manageable and audit readiness a constant.

In summary, a robust Purified Water Storage and Distribution System is indispensable in biotech operations, offering reliability, compliance, and confidence in sensitive biological applications.

No comments:

Post a Comment