In the cosmetics and personal care industry, product quality and consumer safety are directly influenced by water purity. From facial creams to baby lotions, purified water is used as a base ingredient and as a cleaning agent during production.

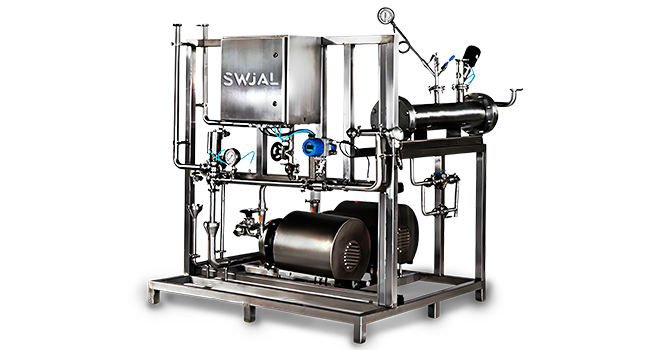

The storage and distribution system must ensure microbiologically safe and chemically stable water throughout the production cycle. Built with SS316L stainless steel, the system employs orbital welding, sloped piping, and continuous loop design to prevent microbial growth and ensure smooth drainage. Flow velocities of 1.5 m/s or more are maintained to avoid stagnation.

|

| Purified Water Storage and Distribution System for the Cosmetics & Personal Care Industry |

Automated systems with PLC/SCADA integration offer control over temperature, conductivity, TOC, and microbial count, with alerts and audit trails to support GMP and ISO compliance. Sanitization may be performed using hot water or ozone systems, and additional measures like UV disinfection may be used for sensitive formulations.

Applications include water used in emulsions, gels, serums, and eye-care products, as well as cleaning of process vessels and pipelines. The system supports allergen-free, preservative-minimized product development, which is increasingly demanded by consumers.

As formulations grow more complex and consumers demand higher product purity, cosmetic manufacturers must adopt water systems that eliminate the risk of contamination. The integration of hygienic valves, high-grade seals, and inline sensors further enhances system reliability and ensures purity at every stage of manufacturing. This provides a consistent base for product performance, skin safety, and customer satisfaction.

Environmental sustainability and branding are also crucial in the personal care market. Companies are now opting for water systems that support green operations through reduced water and energy usage. These eco-friendly solutions not only lower operational costs but also align with clean beauty values and enhance brand credibility.

To conclude, a high-performance Purified Water Storage and Distribution System is vital for maintaining product quality, brand trust, and regulatory compliance in the cosmetics industry.